Carbon fiber composites are widely used across aerospace, automotive, medical, and sporting industries due to their high strength-to-weight ratio and excellent mechanical properties. However, these advantages come with a challenge: carbon fiber is notoriously difficult to cut cleanly without causing fraying, delamination, or excessive tool wear. Traditional cutting methods often fall short in precision or surface quality. This is where diamond wire cutting proves to be the optimal solution for carbon fiber composites.

Carbon fiber composites are made of strong carbon fibers embedded in a resin matrix. While the fibers are stiff and abrasive, the resin is relatively brittle. This mismatch in material behavior causes:

Delamination risks during mechanical cutting

Fiber pull-out under shear stress

Heat damage with high-speed or friction-based methods

Excessive tool wear, especially when using carbide or steel blades

These problems demand a cutting solution that is gentle yet precise, and capable of maintaining surface integrity.

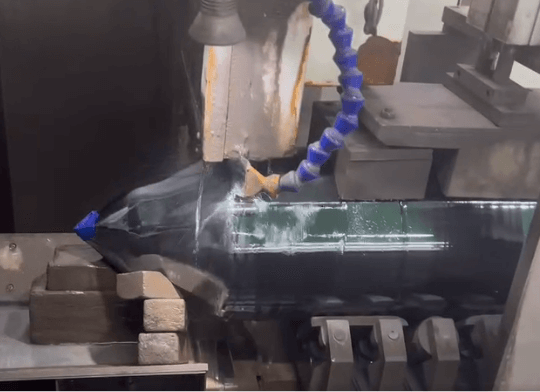

Diamond wire cutting utilizes a continuous or endless wire embedded with industrial diamond particles. As the wire moves at high speed—up to 80 m/s—it grinds through materials with minimal force and friction. This cutting process:

Produces less vibration than sawing or routing

Minimizes heat buildup

Reduces mechanical stress on the composite layers

The result is a cleaner cut with minimal fiber disruption.

• Exceptional Edge Quality

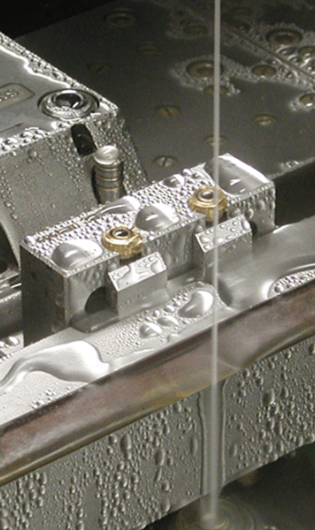

Diamond wire produces smooth, burr-free edges that require little to no post-processing. This is essential for precision parts and structural components.

• Low Delamination Risk

Unlike traditional saws that exert pressure on the fiber matrix, diamond wire gradually abrades the material, preserving the bond between fibers and resin.

• Thin Kerf and High Precision

Wire diameters as small as 0.3 mm allow for narrow cuts and tight tolerances. This is ideal for cutting intricate geometries or maximizing material yield.

• Cool and Clean Cutting

The process generates minimal heat, avoiding thermal degradation of the resin. With proper dust extraction, it also maintains a clean working environment.

• Long Tool Life

Diamond wire loops have excellent durability, even under continuous use, reducing consumable costs over time.

|

Cutting Method |

Surface Quality |

Heat Affected Zone |

Tool Wear |

Delamination Risk |

|---|---|---|---|---|

|

Diamond Wire Cutting |

Excellent |

Very Low |

Low |

Minimal |

|

CNC Router |

Moderate |

High |

High |

High |

|

Waterjet Cutting |

Good |

None (cold cutting) |

Medium |

Medium |

|

Laser Cutting |

Poor |

High (resin burns) |

None |

Very High |

As the table shows, diamond wire cutting outperforms in critical aspects of composite processing.

Carbon fiber components processed with diamond wire cutting are commonly used in:

Aerospace structural parts

Drone frames and components

Automotive panels and brackets

Sporting equipment

Medical device enclosures

The high dimensional stability and edge cleanliness offered by this method make it the preferred choice for industries demanding top-tier quality.

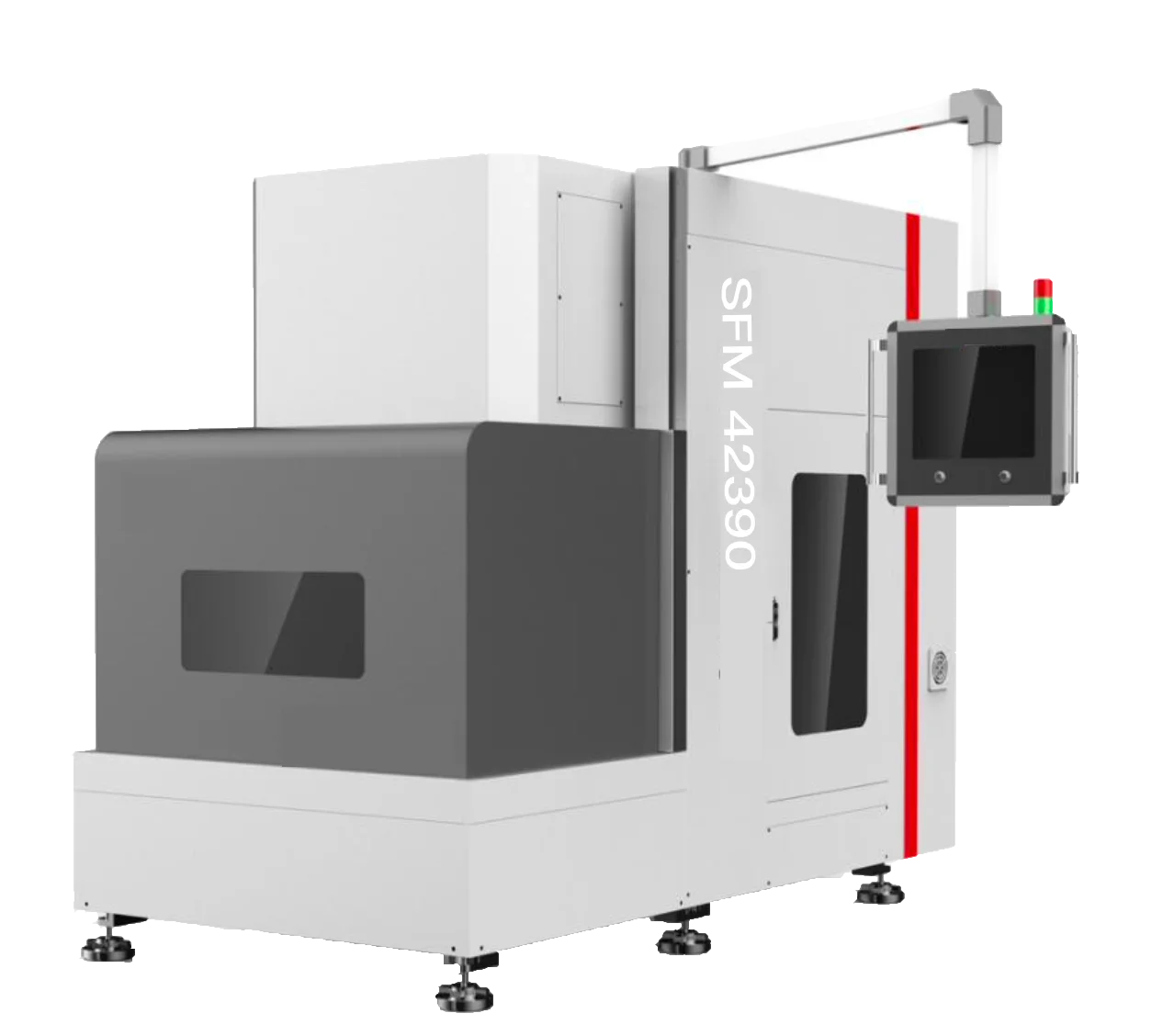

Diamond wire cutting stands out as the most effective and reliable method for cutting carbon fiber composites. It offers a perfect balance of precision, surface finish, and material preservation—qualities that are difficult to achieve with traditional tools. As industries continue to adopt composite materials in mission-critical applications, adopting advanced cutting technologies like diamond wire cutting is essential for maintaining performance, efficiency, and production consistency.