In manufacturing sectors where precision and efficiency are paramount, cutting hard and brittle materials presents a constant challenge. Materials such as sapphire, silicon carbide, optical glass, quartz, ceramics, and graphite require a cutting method that ensures clean edges, minimal chipping, and tight tolerances. An industrial wire saw offers the ideal solution—providing high-precision results, reducing material waste, and adapting to diverse industrial needs.

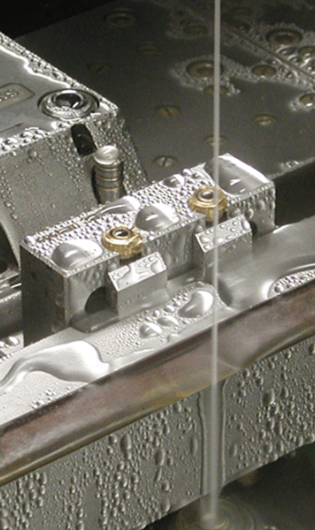

An industrial wire saw operates by running a diamond-coated wire at high speed through the workpiece. The abrasive particles on the wire’s surface grind away material with minimal mechanical stress, preventing cracks or deformation.

Key operational features include:

Diamond-Coated Wire – Ensures superior cutting capability for ultra-hard materials.

Variable Wire Speed – Adjustable up to 80 m/s to optimize cutting efficiency for different materials.

Automatic Tensioning – Maintains wire stability for consistent performance.

Precision Feed Systems – CNC-controlled axes achieve ±0.01 mm positioning accuracy.

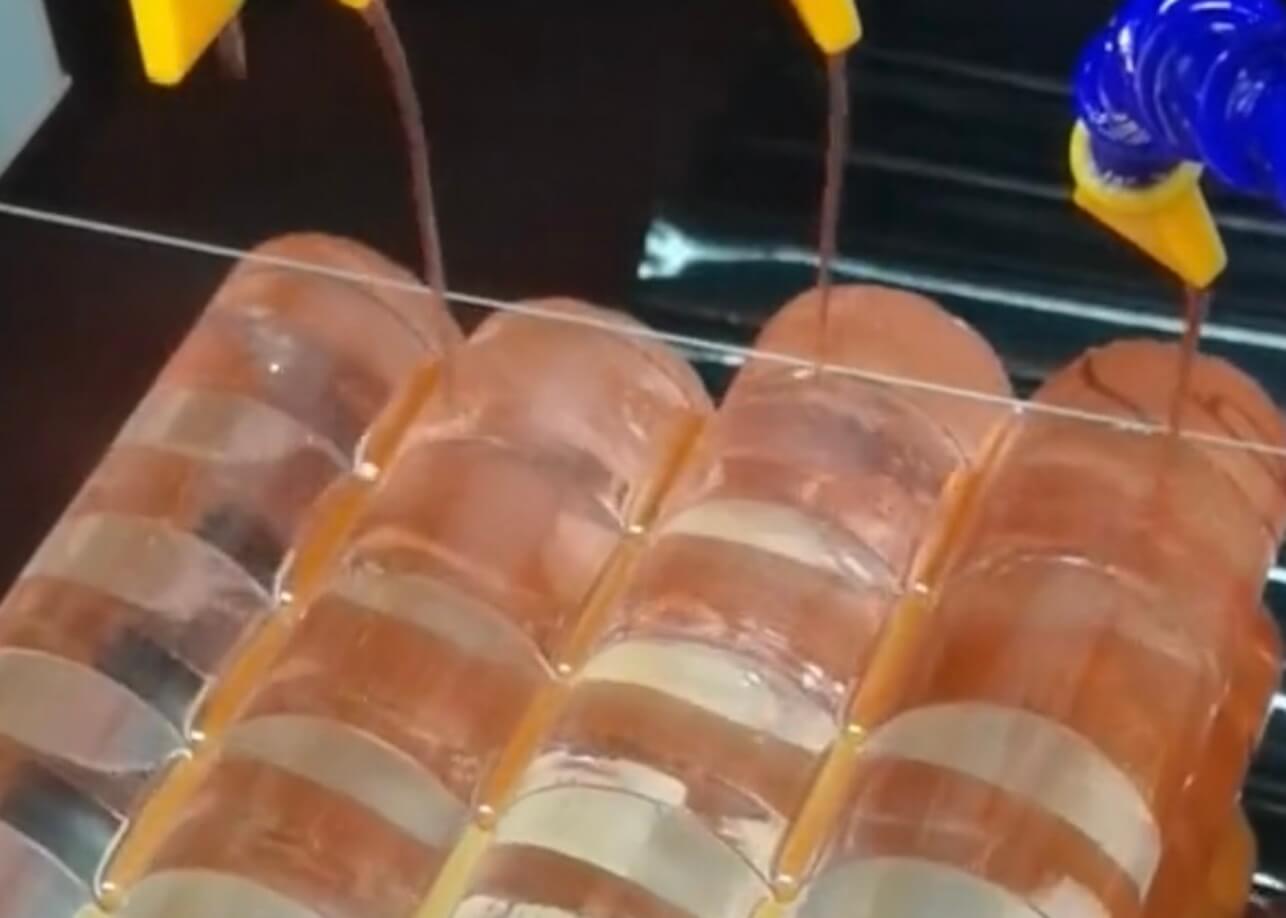

Cooling and Lubrication Options – Supports both dry cutting with dust extraction and wet cutting with oil-based or water-based coolants.

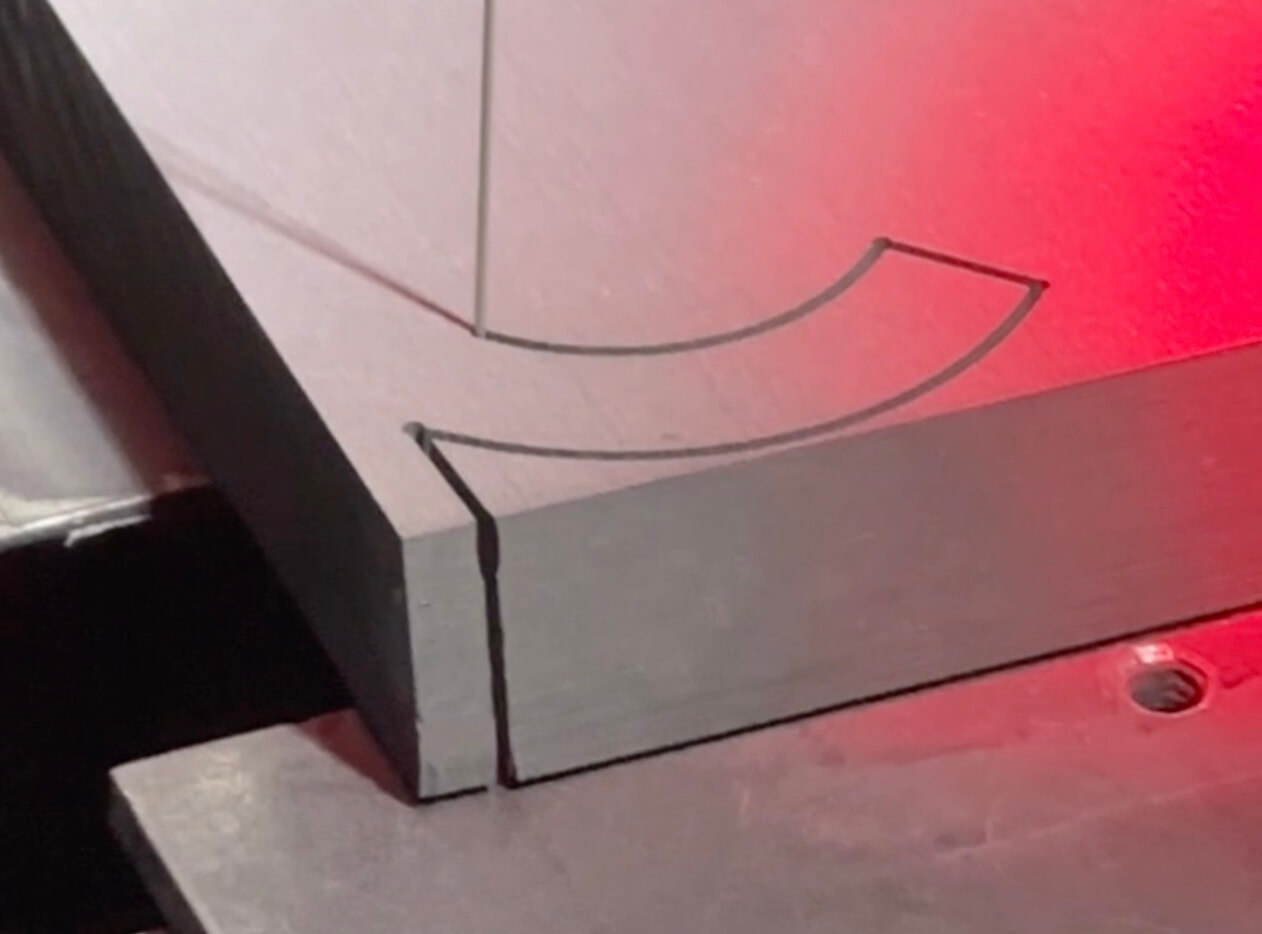

This method achieves narrow kerf widths—often as low as 0.4 mm—resulting in higher material yield and reduced post-processing requirements.

Processing hard materials like sapphire or silicon carbide demands exceptional stability and precision. The industrial wire saw delivers:

Ultra-Smooth Cutting Surfaces – Reducing or eliminating extensive polishing.

High Dimensional Accuracy – Achieving tolerances within ±0.03 mm.

Low Material Waste – Narrow kerf conserves costly raw materials.

Versatility – Suitable for a range of shapes, from simple slices to complex contours.

Reduced Heat Damage – Minimal thermal influence preserves material integrity.

These capabilities make industrial wire saws indispensable for high-value materials where every millimeter counts.

Brittle materials are prone to cracking and chipping under conventional cutting methods. Industrial wire saws address these issues across industries:

1. Optical Components

Used for cutting lenses, prisms, and filters with superior edge quality, minimizing polishing time.

2. Semiconductor Wafers

Ideal for slicing silicon, sapphire, and other substrates used in microelectronics and LED manufacturing.

3. Quartz and Technical Ceramics

Delivers precision cuts for components used in aerospace, defense, and scientific instruments.

4. Graphite and Composites

Achieves clean cuts in brittle carbon-based materials for applications such as EDM electrodes and aerospace tooling.

When compared to blade saws, band saws, or inner diameter saws, the industrial wire saw provides:

Higher Precision – Wire saws maintain accuracy over long production runs.

Lower Kerf Width – Reduces raw material waste significantly.

Wider Material Compatibility – Handles materials that dull or damage traditional blades.

Longer Consumable Life – Endless wire loops last longer than many abrasive blades.

Cleaner Surface Finish – Minimizes secondary finishing requirements.

Selecting an industrial wire saw depends on:

Material Type – Sapphire, ceramics, glass, or composites.

Cutting Dimensions – Thickness, diameter, and part size.

Production Volume – From R&D and prototyping to high-throughput manufacturing.

Automation Needs – Manual feed, semi-automatic, or fully CNC-controlled systems.

Environment – Cleanroom compatibility or heavy-duty shop-floor models.

Common configurations include:

Desktop Precision Saws – For laboratories and small parts.

Mid-Size Gantry Systems – For mixed slicing and shaping tasks.

Large-Scale Industrial Models – For mass production of large ingots or panels.

An industrial wire saw is a versatile and precise solution for cutting hard and brittle materials across multiple industries. With its ability to deliver smooth surfaces, tight tolerances, and minimal waste, it outperforms traditional cutting tools in both quality and efficiency. Whether you are manufacturing optical components, semiconductor wafers, or advanced ceramics, investing in a wire saw can significantly enhance productivity and product quality.

👉 Click to view our industrial wire saw equipment designed for high-precision cutting of hard and brittle materials, and explore detailed specifications.