Cutting technology plays a crucial role in modern industries. From basic infrastructure to precision manufacturing, choosing the right cutting technology is crucial for ensuring efficiency, accuracy, and cost-effectiveness. Among various cutting techniques, annular diamond wire cutting is increasingly favored across many industries for its unique advantages.

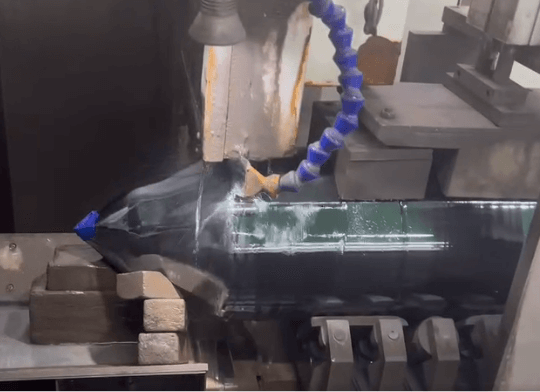

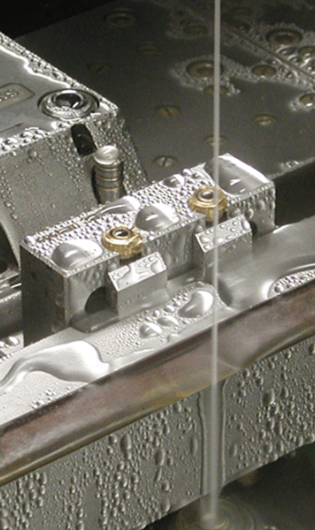

Annular diamond wire cutting employs diamonds as the cutting medium, cutting through materials using a high-speed rotating wire. This method’s main characteristics include high-precision cutting, minimal material waste, and low damage to the material being cut. Moreover, it allows for accurate cutting on complex and small shapes, often challenging with traditional techniques.

Traditional cutting methods, such as diamond band saws, waterjet cutting, and laser cutting, each have their unique applications and limitations. Diamond band saws, while suitable for large-scale cutting, fall short in precision and flexibility. Waterjet cutting is effective for softer materials but less effective on hard materials. Although laser cutting is precise, it’s costly and may not be the best choice for certain materials.

Annular diamond wire cutting surpasses traditional techniques in several aspects. In terms of efficiency, it can quickly cut through hard materials, reducing work time. Regarding accuracy, this technology provides unmatched finesse, especially when dealing with complex patterns or small components. Cost-wise, although the initial investment might be higher, the long-term cost-effectiveness due to high efficiency and low material wastage is significant.

Considering a practical case, a company specializing in precision component manufacturing adopted annular diamond wire cutting technology, successfully enhancing production efficiency and reducing material waste. This technology enabled them to cut complex parts quickly and accurately, significantly improving throughput and product quality.

In summary, annular diamond wire cutting technology outperforms traditional cutting techniques in multiple aspects. It not only offers higher cutting efficiency and precision but also shows significant cost-effectiveness in long-term operation. For businesses seeking to improve production efficiency, reduce material waste, and achieve precise cutting, annular diamond wire cutting technology is an ideal choice. With continuous technological innovations and improvements, annular diamond wire cutting is expected to play an increasingly significant role in future industrial applications.