IR filter windows, also known as infrared optical filters, are critical components in a wide range of applications—from thermal imaging and night vision to gas sensing and medical diagnostics. These filters are often made of hard and brittle materials like germanium, silicon, sapphire, or chalcogenide glass. To maintain their optical integrity and performance, they must be cut with extremely high precision and minimal surface damage.

Cutting IR filter windows with diamond wire has emerged as a reliable, efficient, and low-stress method that meets the demanding requirements of modern infrared technologies. This article explores the benefits, process, and suitability of diamond wire cutting in the production of IR optical components.

profile cut machine

IR filter substrates pose unique machining challenges due to their physical and chemical properties:

Brittle nature: Materials like sapphire or germanium can crack or chip easily during mechanical processing.

High hardness: Conventional tools wear quickly when machining hard materials.

Tight tolerances: Optical filters require precision thickness control, flatness, and low edge damage.

Surface sensitivity: Scratches or subsurface damage can degrade infrared transmittance.

These challenges rule out many traditional cutting methods like dicing saws, laser cutting, or abrasive blades, especially when delicate, thin wafers or miniaturized filters are involved.

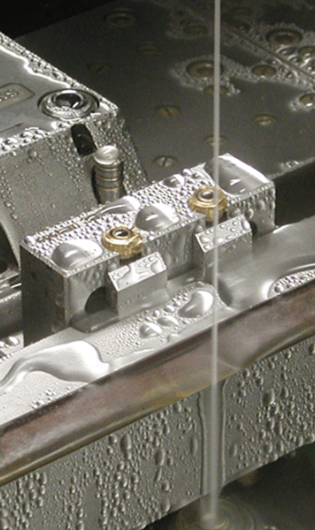

Diamond wire cutting addresses these issues through a contact-based, low-force slicing method using an ultra-thin wire embedded with diamond abrasives. The wire is arranged in a closed loop (endless diamond wire) and runs at high speeds—up to 80 m/s—ensuring clean and continuous cutting.

Key advantages include:

Minimal chipping and edge defects due to low mechanical stress

Tight thickness control with achievable tolerances down to ±0.03 mm

Smooth cut surfaces that reduce or eliminate the need for post-polishing

Material versatility, supporting brittle infrared materials like ZnSe, Ge, Si, CaF₂, and sapphire

Reduced kerf width, minimizing material loss and improving yield

This method is especially useful for cutting thin IR filters used in compact sensor modules or precision IR optical stacks.

The cutting process begins by mounting the IR filter blank or substrate onto a precision stage. Depending on the desired cut geometry, the machine can be programmed for straight slicing, angled cuts, or even profiled contours.

Key process parameters include:

Wire diameter: Typically 0.3 to 0.65 mm depending on material thickness and desired surface quality

Wire speed: Adjustable from 10 to 80 m/s to optimize cutting rate vs surface damage

Feed rate: Slower for ultra-thin filters (as low as 0.1 mm), faster for thicker parts

Dry or wet cutting: Water or white mineral oil may be used depending on dust control and material sensitivity

Many systems used for IR optics, such as Vimfun’s SG and SGR series machines, include features like automatic tensioning, CNC-controlled slicing, and wire break detection to ensure safety and repeatability.

|

Method |

Advantages |

Limitations |

|---|---|---|

|

Diamond Wire Cutting |

High precision, low kerf, low stress, minimal edge chipping |

Slower than laser on some materials |

|

Laser Cutting |

Fast, contactless |

Causes heat-affected zones, microcracks, and redeposition |

|

Dicing Saw |

Common in mass production |

Generates chipping and wider kerf |

|

Mechanical Sawing |

Low cost |

Poor surface finish, limited precision |

Diamond wire cutting provides the best combination of accuracy, surface quality, and material compatibility, especially for low-volume production, prototyping, and specialty IR components.

Cutting IR filter windows with diamond wire is suitable for:

Infrared camera lens components

Thermal detection modules in defense and automotive systems

Medical diagnostic IR sensors

Gas detection and spectroscopy filters

Space-grade IR optics with complex geometries

The method ensures the optical integrity of the material is preserved, which is essential for maintaining spectral accuracy and transmission efficiency in the final application.

Conclusion

As optical technologies push the limits of miniaturization and performance, cutting IR filter windows with diamond wire offers a scalable and precise solution for advanced manufacturing. The process minimizes damage, preserves material integrity, and delivers consistent results across a wide range of brittle IR materials.

Whether you’re producing prototype filters or scaling up for specialized sensor production, diamond wire cutting is an ideal choice for achieving the high standards demanded in modern infrared optics.

👉 Click to view our diamond wire cutting solutions tailored for IR filter manufacturing.