In modern material processing, achieving clean, precise cuts is paramount—especially for industries dealing with brittle or high-value materials such as optical glass, silicon carbide, or graphite. Two cutting technologies often considered are wire saw wire and band saw blades. While both serve the purpose of slicing through solid materials, they differ significantly in structure, cutting quality, and applications. This article explores which method delivers cleaner precision cuts and why wire saw wire is gaining traction in advanced manufacturing.

Band Saw Blades use a continuous steel loop with teeth that cut by mechanical abrasion. These blades are relatively wide, and the cutting action generates significant vibration and thermal stress. The blade’s thickness typically ranges from 0.5 mm to 1.2 mm, resulting in a wider kerf and more material loss.

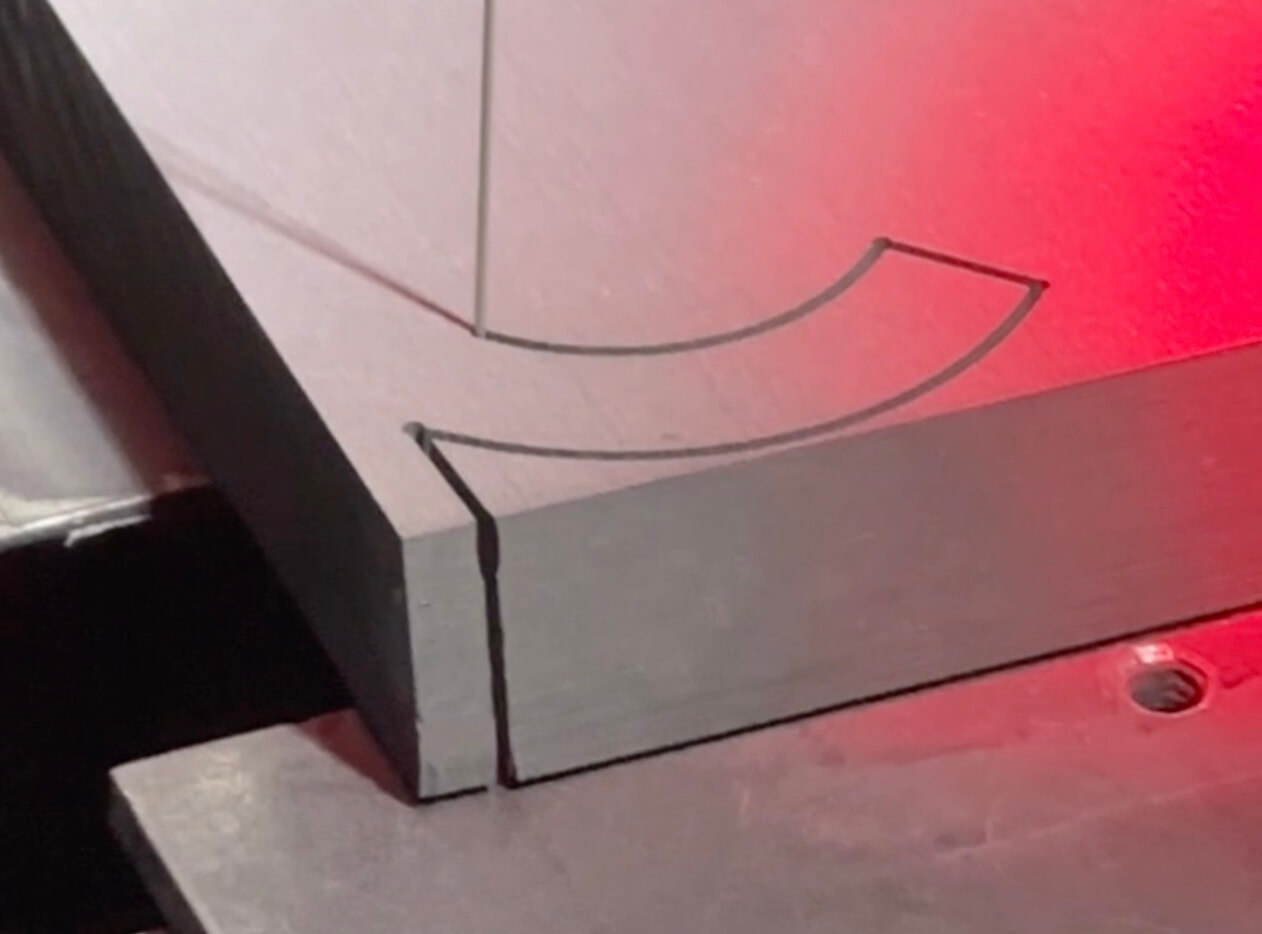

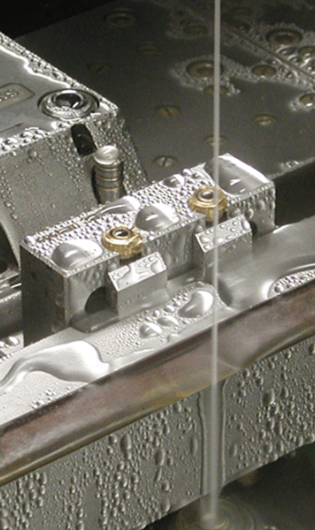

Wire Saw Wire, on the other hand, is typically an endless loop of diamond-coated wire. The wire, often with a diameter as small as 0.35 mm, operates at high linear speeds (up to 80 m/s), enabling a continuous, low-vibration cut. The diamond particles act as the abrasive medium, making it particularly effective for hard, brittle materials.

A key performance metric is the cleanliness of the cut surface. Wire saw wire excels in delivering mirror-smooth finishes with minimal chipping and fewer wire marks. The low-vibration process reduces internal stress in the workpiece and often eliminates the need for extensive secondary polishing.

In contrast, band saw blades frequently leave rougher surfaces with visible tool marks and micro-fractures, especially when cutting brittle materials like quartz or sapphire. These imperfections necessitate further grinding or lapping, increasing production time and cost.

Precision cutting demands tight tolerances and minimal kerf. Wire saw wire can achieve cutting tolerances within ±0.03 mm, with positioning accuracy up to ±0.01 mm, depending on the machine model. The ultra-thin wire also results in a kerf as narrow as 0.4 mm, minimizing material waste—an essential factor when processing expensive substrates.

Band saw blades, due to their thickness and coarser operation, cannot match this level of precision. Their wider kerf (often over 1 mm) leads to significantly more material loss, and their limited flexibility hinders complex contour or micro-part cutting.

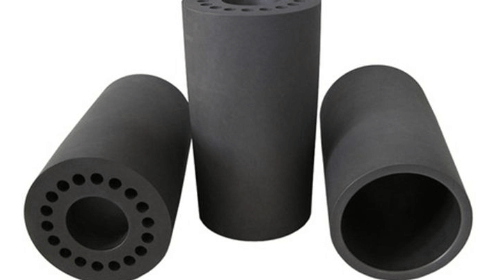

Wire saw wire is widely used in high-tech sectors: semiconductor wafer slicing, optical lens shaping, graphite electrode processing, and advanced ceramics manufacturing. It handles delicate, layered, or high-hardness materials with ease, supporting both dry and wet cutting modes.

Band saws remain suitable for general-purpose tasks, such as cutting metals, plastics, or wood, especially in rough or structural fabrication. However, they struggle with ultra-hard or high-precision materials.

👉 Click to explore wire saw wire solutions for semiconductor and optical industries.

Though wire saw wire machines typically have higher upfront costs, they compensate through longer tool life (5–7 days of continuous use per wire), lower post-processing needs, and minimal material waste. The diamond-coated wire maintains sharpness over extended periods, especially in dry cutting configurations with minimal debris.

Band saw blades require more frequent replacement and generate higher operational noise and dust levels, especially under demanding loads.

When it comes to cleaner, more precise cutting—particularly for brittle, high-value materials—wire saw wire significantly outperforms band saw blades. Its finer kerf, superior surface finish, and higher dimensional accuracy make it the tool of choice for modern precision applications.

For industries seeking efficient, low-waste, high-accuracy solutions, transitioning to diamond wire saw technology is a future-proof investment.