+1-778-938-0103

(086)130-2773-8908

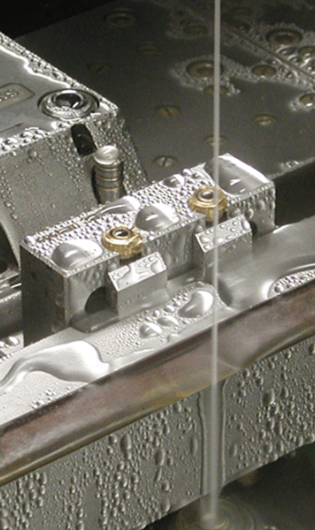

| Item Name | Item Content |

| X, Y, and Z axle movement positioning precision | 0.01mm |

| X, Y, and Z axle repeated positioning precision | 0.008mm |

| Planeness of the workbench | ≤0.02mm |

| X and Y perpendicularity | 0.015/400mm |

| X, Y, and Z axle working stroke | 400x400x110mm |

| Dimensions of the workbench | 480x480mm |

| Distance from spindle nose to table | 80-190mm |

| Fast moving speed | 10m/min |

| Maximum cutting feed speed | 8m/min |

| Spindle motor output power | 2.2Kw |

| Spindle speed (Stepless speed change) | 0-24000rpm |

| Working voltage | Single-phase 220V/50Hz±10% |

| Driving system | Servo |

| Machine tool weight | 900Kg |

| Electric cabinet dimensions | 600x590x1360mm |

| Appearance dimensions of the machine tool | 910x1010x1560mm |

| Optional items | 3.5 axis (Rotating shaft)/double Z axis |