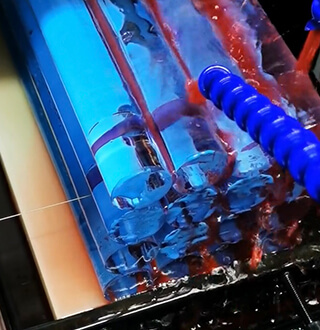

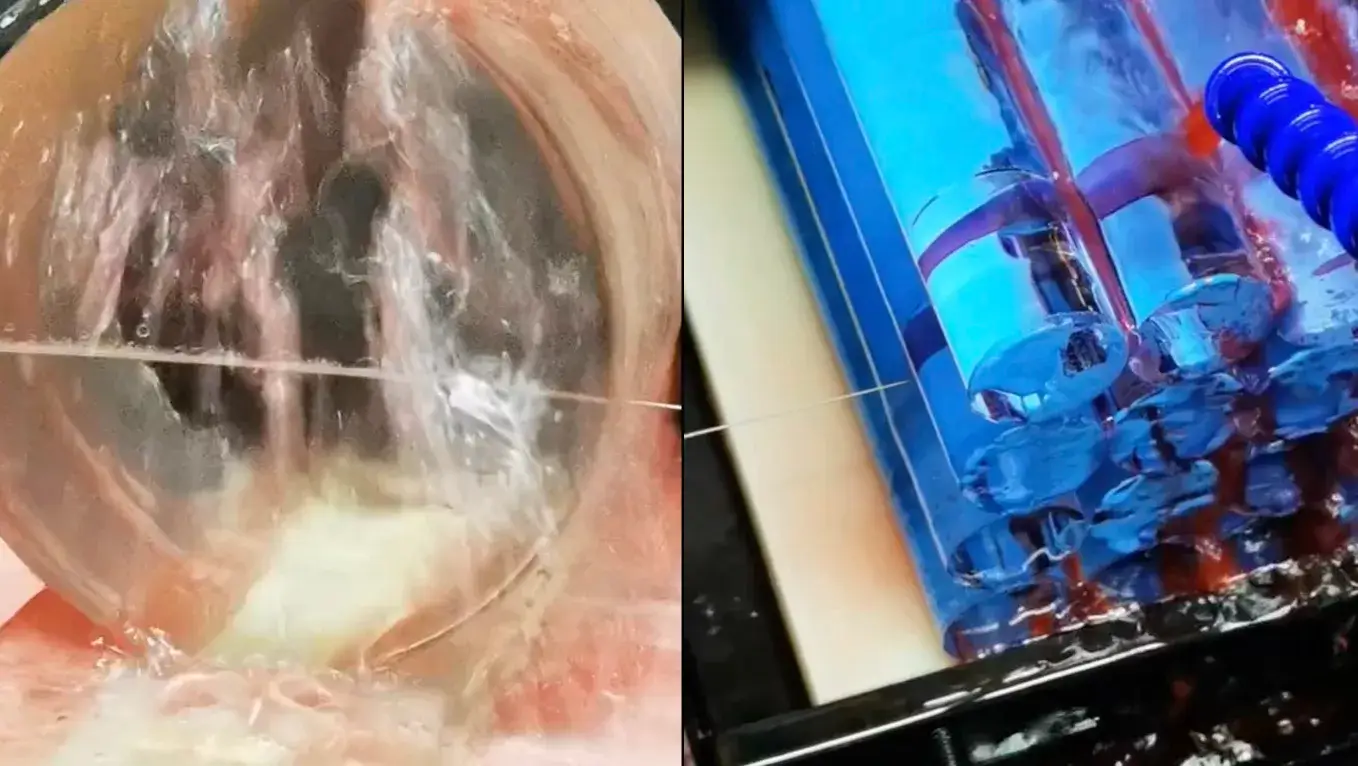

The future of optical glass cutting is being reshaped by the Endless Diamond Wire Saw, a technology that promises to bring unprecedented efficiency and precision. This innovative method is set to revolutionize the way optical glass is cut, offering significant advancements over traditional cutting methods. Its key advantage lies in its ability to make extremely precise cuts with minimal material waste, which is crucial in industries where optical glass is used, such as photonics, telecommunications, and high-precision optics.

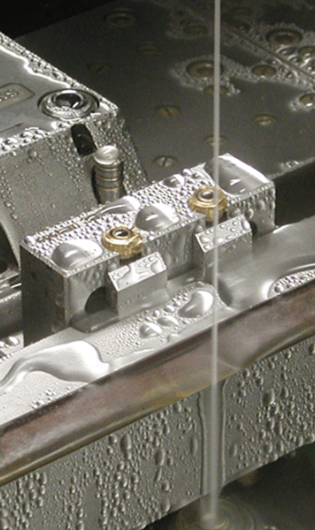

The Endless Diamond Wire Saw’s thin, diamond-embedded wire provides a cleaner cut, reducing the likelihood of microfractures and improving the overall quality of the glass. This technology also allows for intricate shapes and designs to be cut more efficiently, opening up new possibilities for complex optical components.

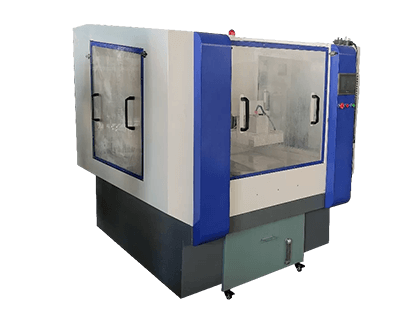

Furthermore, its efficiency in cutting and reduced operational costs position the Endless Diamond Wire Saw as a sustainable and cost-effective solution. As the demand for high-quality optical glass grows, this technology is poised to become an industry standard, heralding a new era in optical glass manufacturing with its precision, speed, and reduced environmental impact.