| Number | Parameter | Value or Specification |

| 1 | Maximum Workpiece Length (mm) | 300 |

| Maximum Workpiece Width (mm) | 300 | |

| 2 | Maximum Workpiece Height (mm) | 300 |

| 3 | Worktable Y-Axis Travel (mm) | 300 |

| 5 | Worktable Z-Axis Travel (mm) | 300 |

| 10 | Maximum Diamond Wire Speed (m/s) | 27(Max) |

| 13 | Minimum Feed Increment Y-Axis (mm) | 0.01 |

| 14 | Minimum Feed Increment Z-Axis (mm) | 0.01 |

| 15 | Repeat Positioning Accuracy Y-Axis (mm) | ±0.02 |

| 16 | Repeat Positioning Accuracy Z-Axis (mm) | ±0.02 |

| 20 | Total Power Consumption (kW) | 2.5 |

| 21 | Power Supply (Three-phase Five-wire) | AC220V 50Hz |

| 23 | Equipment Dimensions (Length×Width×Height) (mm) | Approximately 1000*800*1800 |

| 24 | Total Weight (kg) | Approximately 450 |

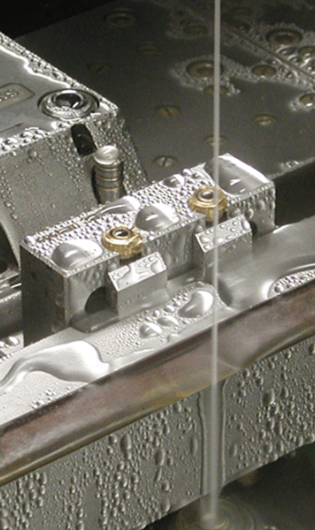

Model SG30 Optical Glass Cutting Machine has a closed-loop diamond wire that can move in a single direction without the need for reversing. The circular diamond wire enables high linear speeds. As a result, it allows for fast cutting speeds and maintaining superior cutting surface quality.

Say goodbye to outdated cutting methods and welcome the future of optical glass cutting machine with our cutting-edge Endless Wire Saw Model SG30.

Specifically engineered to address the limitations of traditional inner diameter saws, the SG30 sets new standards in efficiency, precision, and versatility.

Click To Watch More Videos Showing Our Cutting Machine In Action.

| Inner Diameter Saw: | Endless Wire Saw: |

| An inner diameter saw, also known as an ID saw, is a traditional cutting machine used for various materials, including optical glass. This type of saw features a circular blade with a fixed diameter. The material to be cut is positioned around the blade, and the blade rotates to cut through the material. | An endless wire saw, on the other hand, is a cutting machine that uses a continuous loop of cutting wire, often coated with abrasive materials like diamond particles. This wire runs on a set of pulleys and moves through the material to make cuts. |

| key characteristics of inner diameter saws: | key characteristics of endless wire saws: |

1, Limited Cutting Depth: Inner diameter saws are limited by the size of the circular blade. The cutting depth is determined by the radius of the blade, which can restrict the thickness of the workpiece that can be cut. 2, Material Waste: The circular blade of an inner diameter saw results in a significant amount of material waste in the form of the cut width and the circular core. This is particularly pronounced when cutting out shapes or patterns from a larger sheet. 3, Cutting Efficiency: While inner diameter saws are effective for certain applications, their cutting efficiency can be lower when compared to more advanced cutting technologies. | 1, Continuous Cutting: The continuous loop of the cutting wire allows for non-stop cutting of workpieces, regardless of their size or shape. This eliminates the limitations of the blade’s diameter and enables the cutting of large and thick materials. 2, Minimal Material Waste: Endless wire saws produce minimal material waste due to the thinness of the cutting wire. This is especially beneficial when cutting valuable materials like optical glass, where reducing waste is crucial. 3, Versatility: Endless wire saws are versatile and adaptable to various materials and shapes. They are particularly effective for cutting intricate patterns, complex geometries, and irregular shapes. 4, Efficiency: Endless wire saws often offer higher cutting efficiency due to their continuous cutting action and reduced material waste. |