+1-778-938-0103

(086)130-2773-8908

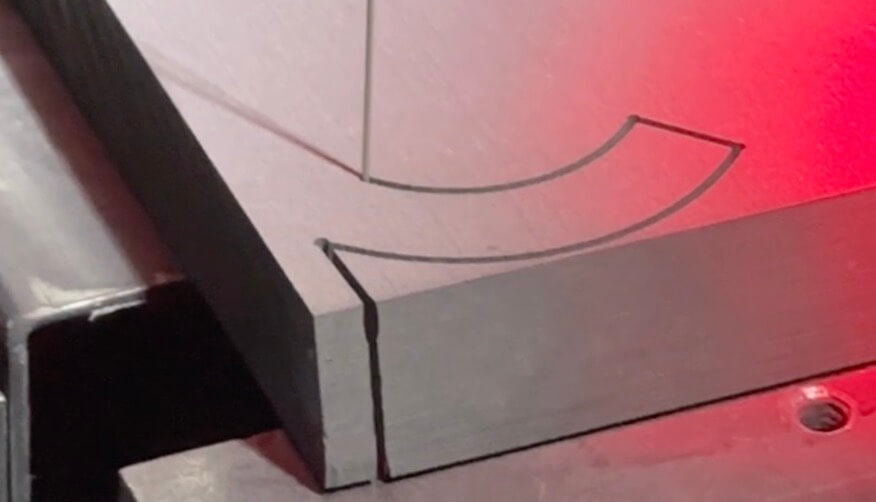

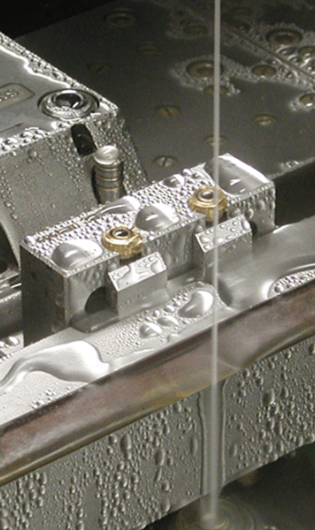

| Graphite Barrel Shaper SVC150-R | ||

| Number | Parameter | Value or Specification |

| 1 | Maximum Workpiece Height (mm) | 600-1200 |

| 2 | Maximum Workpiece Diameter (mm) | 600-1600 |

| 3 | Maximum Diameter Machine Can Cut (mm) | 600-1400 |

| 4 | Worktable X-Axis Travel (mm) | 350 |

| 10 | Maximum Diamond Wire Speed (m/s) | 84 (Max) |

| 13 | Minimum Feed Increment Y-Axis (mm) | 0.01 |

| 14 | Minimum Feed Increment R-Axis (mm) | 0.01° |

| 15 | Repeat Positioning Accuracy Y-Axis (mm) | ±0.02 |

| 16 | Repeat Positioning Accuracy R-Axis (mm) | 0.1° |

| 20 | Total Power Consumption (kW) | 8 |

| 21 | Power Supply (Three-phase Five-wire) | AC380V 50Hz |

| 22 | Air Supply (MPa) | 0.6 |

| 23 | Equipment Dimensions (Length×Width×Height) (mm) | Approximately 3500×2500×2800 |

| 24 | Total Weight (kg) | Approximately 3500 |

Click To Watch More Videos Showing Our Cutting Machine In Action.