Overview

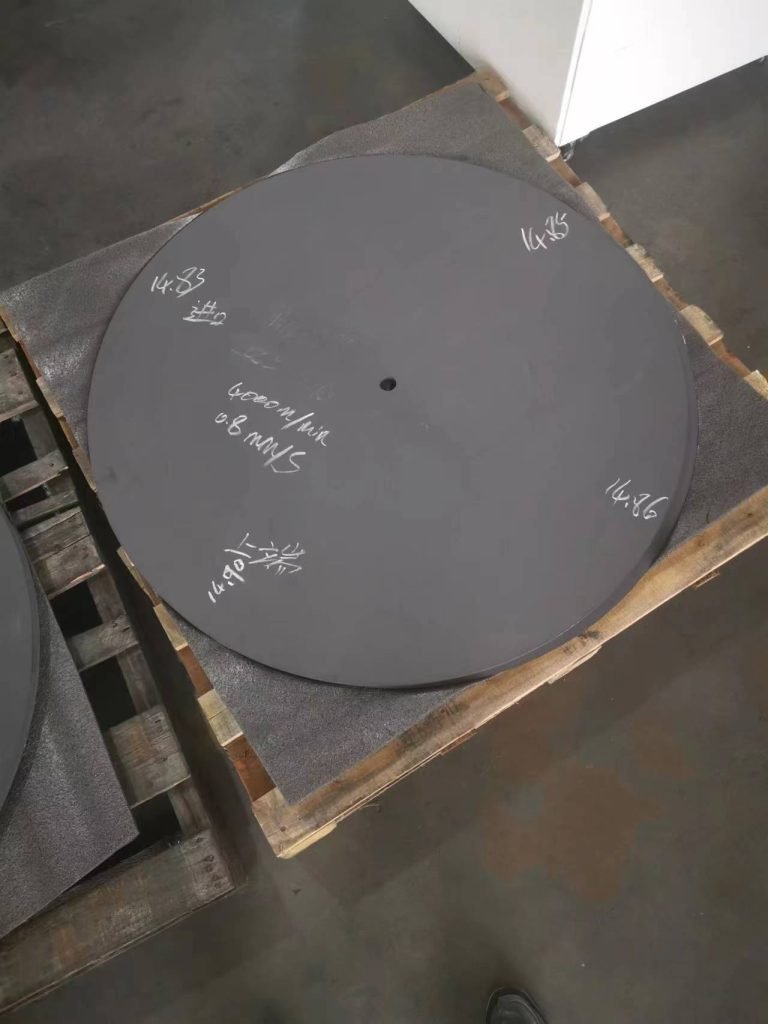

This is a story about Graphite Block Slicing. In the world of industrial manufacturing, accomplishing challenging feats is the mark of progress. In this case, our client faced the daunting task of precisely slicing massive graphite blocks, some as vast as 1.2 meters in every dimension. These blocks took various forms, including squares and circles, and the goal was to transform them into a multitude of thin plates, ranging from mere millimeters to substantial centimeters in thickness.

The client’s choice of traditional bandsaw technology posed significant challenges:

– Blade Fatigue: Bandsaw blades struggled to withstand the rigorous slicing of these massive graphite blocks, leading to frequent breakages and production setbacks.

– Surface Quality Constraints: Cuts executed by bandsaws often resulted in less-than-optimal surface quality, necessitating extensive post-processing and finishing.

– Dust Quandaries:The wide kerf generated by bandsaws unleashed excessive dust, fostering adverse health and environmental implications.

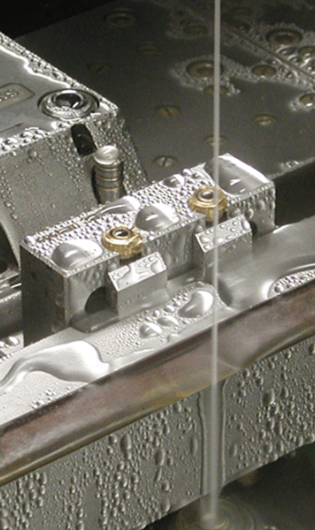

Our response was a specialized cutting machine designed to meet these exacting requirements:

– Machine Model: SVS120-120

– Robust Engineering: Our machine was meticulously engineered to withstand the rigors of slicing massive graphite blocks, ensuring longevity and consistent performance.

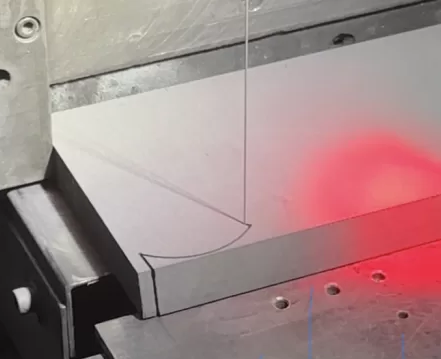

– Diamond-Coated Wire Loop:The machine harnessed a high-density diamond-coated wire loop as its cutting tool, guaranteeing exceptional precision—a hallmark of diamond-based cutting technologies.

– Narrow Kerf Advantages:Our machine produced narrow kerfs, significantly curtailing the generation of disruptive dust during the cutting process.

– Surface Excellence: Cuts were executed with impeccable finesse, resulting in high-quality surfaces that substantially mitigated the need for arduous post-processing.

The cutting setup featured:

– Machine Model:SVS120-120

– Cutting Parameters:

1, Wire Loop Linear Speed: 60 M/S

2,Cutting Feed Rate: 48 MM/MIN

– Material Size:* DIA 970 MM.

During a pivotal pre-shipment inspection, our client bore witness to the transformative potential of our solution. They brought one of their imposing graphite blocks for a test cut—an experience that left them astounded.

– Precision Redefined: Our machine’s diamond-coated wire loop delivered precision beyond measure, ensuring that each plate met the most exacting specifications.

– Efficiency Amplified:The specter of blade breakages was forever dispelled, ushering in newfound production efficiency.

– Surface Perfection: The high-quality surfaces of the resulting plates substantially reduced the need for labor-intensive post-processing and finishing.

The future of graphite block slicing is embracing innovative techniques, notably the integration of the endless diamond wire cut method. This advancement in graphite block slicing is set to revolutionize the process by enhancing precision and minimizing material waste. The endless diamond wire cut approach, with its superior cutting capabilities, is particularly suited for the intricate demands of graphite block slicing. It offers a level of accuracy and efficiency previously unattainable, marking a significant leap forward in the field of graphite block slicing. This method not only optimizes the cutting process but also paves the way for new applications and improvements in various industries relying on precise graphite block slicing.