Profile cutting machines, also known as contour cutting machines, operate based on the principle of precision cutting along predefined profiles or contours. These machines typically utilize computer-controlled cutting heads or tools to follow the specified profile, resulting in precise cuts with minimal material wastage. They are widely used in industries such as automotive, aerospace, and signage for cutting materials like metal, plastic, and composite materials.

Click To Watch More Videos In Our Youtube Channel.

The production and design of profile cutting equipments pose several challenges that require careful consideration and expertise to overcome effectively.

1. **Precision Requirement**: Profile cutting equipments must achieve high levels of precision to accurately follow predefined contours. Even minor deviations or instabilities can result in cutting errors or quality issues, impacting the overall quality of the final product.

2. **Complex Design and Engineering**: Designing and manufacturing profile cutting equipment involves a multidisciplinary approach that encompasses mechanical, electrical, and control engineering aspects. It requires a team of engineers with extensive knowledge and experience to ensure that the equipment’s design and engineering meet the diverse application requirements.

3. **Consideration of Material Properties**: Different materials possess unique characteristics such as hardness, thickness, and surface smoothness, which influence the design and operation of profile cutting equipments. It is essential to account for the material properties to ensure that the equipment can accommodate the cutting requirements of various materials.

4. **Selection of Tools and Cutting Techniques**: Choosing suitable tools and cutting techniques that are appropriate for specific applications is a critical consideration. Different tools and techniques have their advantages and disadvantages, and a comprehensive evaluation is required based on factors such as material type, cutting requirements, and production efficiency.

5. **Safety and Reliability**: Profile cutting equipments typically involve high-speed moving parts and cutting tools, emphasizing the importance of safety and reliability in the design and manufacturing process. Proper safety measures and equipment protection mechanisms must be implemented to ensure the safety of operators and equipment reliability.

6. **Cost and Efficiency Balance**: Achieving a balance between cost and efficiency is essential in the design and manufacturing of profile cutting equipments. High-performance and high-precision equipment often come with higher costs, requiring careful consideration of various factors to ensure that the equipment can deliver the required cutting quality and efficiency within manageable costs.

In summary, the production and design of profile cutting equipments entail addressing multiple challenges and considerations, including precision requirements, complex design and engineering, material properties, tool and cutting technique selection, safety and reliability, and cost-efficiency balance. By carefully addressing these challenges, manufacturers can develop high-performance and reliable contour cutting equipment that meets the diverse needs of the market.

Contour cutting, a process crucial for precision fabrication across various industries, relies on several advanced technologies and specialized equipment. Here’s an overview of the key technologies and equipment commonly used for contour cutting:

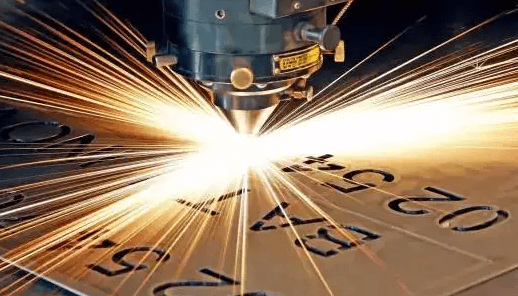

1,Laser Cutting Technology:

laser profile cutting equipment

Laser cutting is renowned for its high precision, speed, and versatility. Utilizing a focused laser beam, this technology can cut through a wide range of materials with exceptional accuracy. Its non-contact nature minimizes material distortion, making it ideal for intricate contour cutting tasks across materials like metals, plastics, and woods.

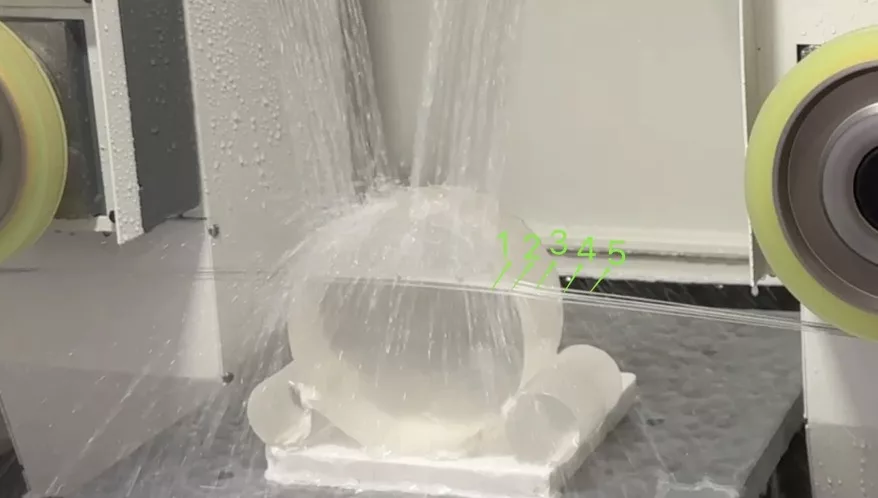

2,Waterjet Cutting Technology:

water jet profile cutting equipment

Waterjet cutting harnesses the power of high-pressure water jets mixed with abrasive particles to slice through materials. This method offers several advantages, including minimal heat-affected zones, suitability for various materials (including metals, stones, and composites), and the ability to produce complex contours with ease.

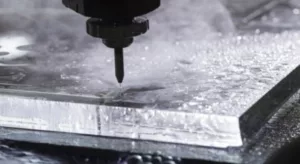

3,CNC Milling Technology:

CNC (Computer Numerical Control) milling involves using computer-controlled rotary cutting tools to remove material from a workpiece, creating precise contours and shapes. This technology offers exceptional flexibility, allowing for the production of complex and intricate parts from a wide range of materials, including metals, plastics, and composites.

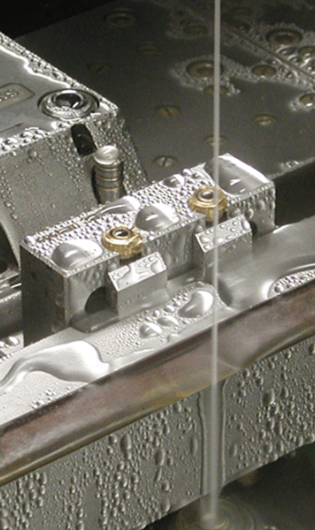

4, Wire Cutting Technology:

profile cutting equipment

Check this 5 wire cutting machine here

Wire cutting employs thin, high-tensile wires, often coated with abrasive materials like diamond, to slice through materials with precision. This method is particularly suitable for creating intricate contours and shapes in materials such as metals, foams, and composites. Wire cutting machines can achieve high levels of accuracy and repeatability, making them indispensable for certain applications.

These technologies and equipment play pivotal roles in various industries, including manufacturing, aerospace, automotive, and electronics. Their ability to deliver precise contour cutting capabilities is instrumental in the production of intricate components, prototypes, and finished products.

In conclusion, the evolution of contour cutting technology and equipment has revolutionized the manufacturing landscape, enabling the production of highly intricate and precise components across a wide range of materials. As industries continue to demand ever-higher levels of precision and efficiency, these cutting-edge technologies will undoubtedly

remain at the forefront of modern manufacturing processes.

Diamond wire cutting and Electrical Discharge Machining (EDM) wire cutting are two commonly used techniques in the realm of wire cutting technology. Each method offers unique advantages and disadvantages, catering to different cutting requirements and material properties. Let’s explore the characteristics of these two techniques:

| Advantages | Disadvantages |

|---|---|

| High precision cuts | Limited cutting speed |

| Low heat generation | Susceptible to wire breakage |

| Minimal material waste | Requires frequent wire replacement |

| Suitable for various materials | Initial equipment cost may be high |

| Flexibility in cutting complex shapes |

| Advantages | Disadvantages |

|---|---|

| Capable of cutting complex shapes | Slow cutting speed |

| No mechanical force on workpiece | Limited material thickness |

| High precision and fine surface finish | Elevated operating costs |

| Ability to cut hardened materials | Potential for electrode wear |

| Minimal material waste |

| Characteristics | Diamond Wire Cutting | EDM Wire Cutting |

|---|---|---|

| Material Compatibility | Suitable for various materials | Limited to conductive materials |

| Cutting Speed | Fast | Relatively slow |

| Material Thickness | Not limited | Limited by material thickness |

| Precision | High | High |

| Heat Generation | Low | None |

| Wire Breakage | Susceptible | Minimal |

| Operating Costs | Moderate to high | Moderate to high |

| Maintenance | Requires frequent wire replacement | Potential for electrode wear |

| Application Flexibility | Suitable for complex shapes | Suitable for complex shapes |

| Waste Material | Minimal | Minimal |

Selecting the appropriate contour cutting equipment is crucial for achieving optimal machining results and efficiency in various manufacturing applications. Here are some key factors to consider when choosing the right equipment:

In summary, when selecting contour cutting equipment, prioritize factors such as precision, material compatibility, cutting speed, versatility, and cost-effectiveness. Considering these factors, diamond wire cutting emerges as a superior option due to its precision, efficiency, and versatility across a wide range of materials and applications.