In the realm of manufacturing, the challenge of cutting large-diameter quartz, especially with a diameter of 2 meters, posed significant obstacles for a client. Traditional equipment, notably inner circle slicing machines, proved both expensive and inadequate for handling such substantial dimensions.

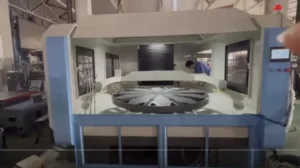

The client decided to explore our innovative SH150-R model, which, although designed for a 1.5-meter diameter, could be customized to scale up to 2 meters. Upon receiving the custom-built equipment, the client conducted trial cuts, and the results exceeded expectations.

2,Uniform Slices without Depressions or Protrusions: The cutting precision of the SH200-R ensured uniform slices without any depressions or protrusions, meeting the client’s stringent quality requirements.

3, Simplified Operation: The equipment’s user-friendly design allowed ordinary workers to learn its operation within just 5 minutes, contributing to increased operational efficiency.

4, Horizontal Cutting Convenience: The SH200-R’s horizontal cutting orientation made material handling exceptionally convenient. Materials could be effortlessly placed on the worktable using a forklift or hoist.

The successful trial cuts and the subsequent implementation of the SH200-R not only addressed the client’s initial challenges but also paved the way for future advancements in large-diameter quartz cutting. The client expressed immense satisfaction with the customized solution, highlighting its efficiency, precision, and ease of use.

This case study exemplifies how customization and innovation in cutting technology can overcome formidable challenges in the manufacturing industry. The SH200-R’s adaptability and performance showcased in cutting large-diameter quartz open new possibilities for manufacturers dealing with oversized materials.

The success story of the SH200-R in cutting 2-meter diameter quartz sets the stage for envisioning its application in various industries dealing with oversized materials. The customizable nature of this solution opens doors for manufacturers seeking precision and efficiency in cutting large-diameter materials.

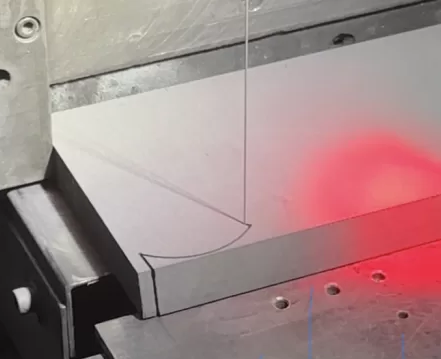

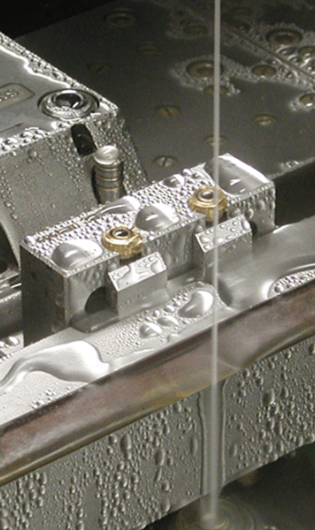

In the realm of large size quartz cutting, various wire cutting equipment plays a pivotal role, each designed to meet the unique challenges of this task. Traditional wire cutting equipment, known for its reliability and precision, has long been the standard in the industry. However, as the demand for more intricate and precise cuts increases, the limitations of conventional wire cutting equipment become apparent, particularly in terms of speed and efficiency. To address these challenges, the newest advancement in wire cutting equipment is the endless diamond wire cut method. This innovative approach revolutionizes large size quartz cutting by combining the precision of traditional wire cutting equipment with enhanced speed and efficiency, making it an ideal solution for complex and large-scale projects.