Graphite, with its exceptional properties of conductivity, thermal resistance, and strength, is a material of significant importance across various industries. To harness its potential fully, specialized equipment known as graphite processing machines has been developed. In recent years, a novel addition to this realm has emerged: endless diamond wire cutting equipment.

This article delves into the world of graphite processing, highlighting the evolution and widespread adoption of circular diamond wire cutting technology.

Graphite processing machines encompass a range of equipment designed for precision cutting, shaping, and machining of graphite materials. These machines are indispensable in industries such as manufacturing, aerospace, and electronics, where graphite’s unique properties are leveraged for diverse applications. Traditional methods of graphite cutting often involved sawing or milling processes, but advancements in technology have led to the emergence of more sophisticated cutting techniques.

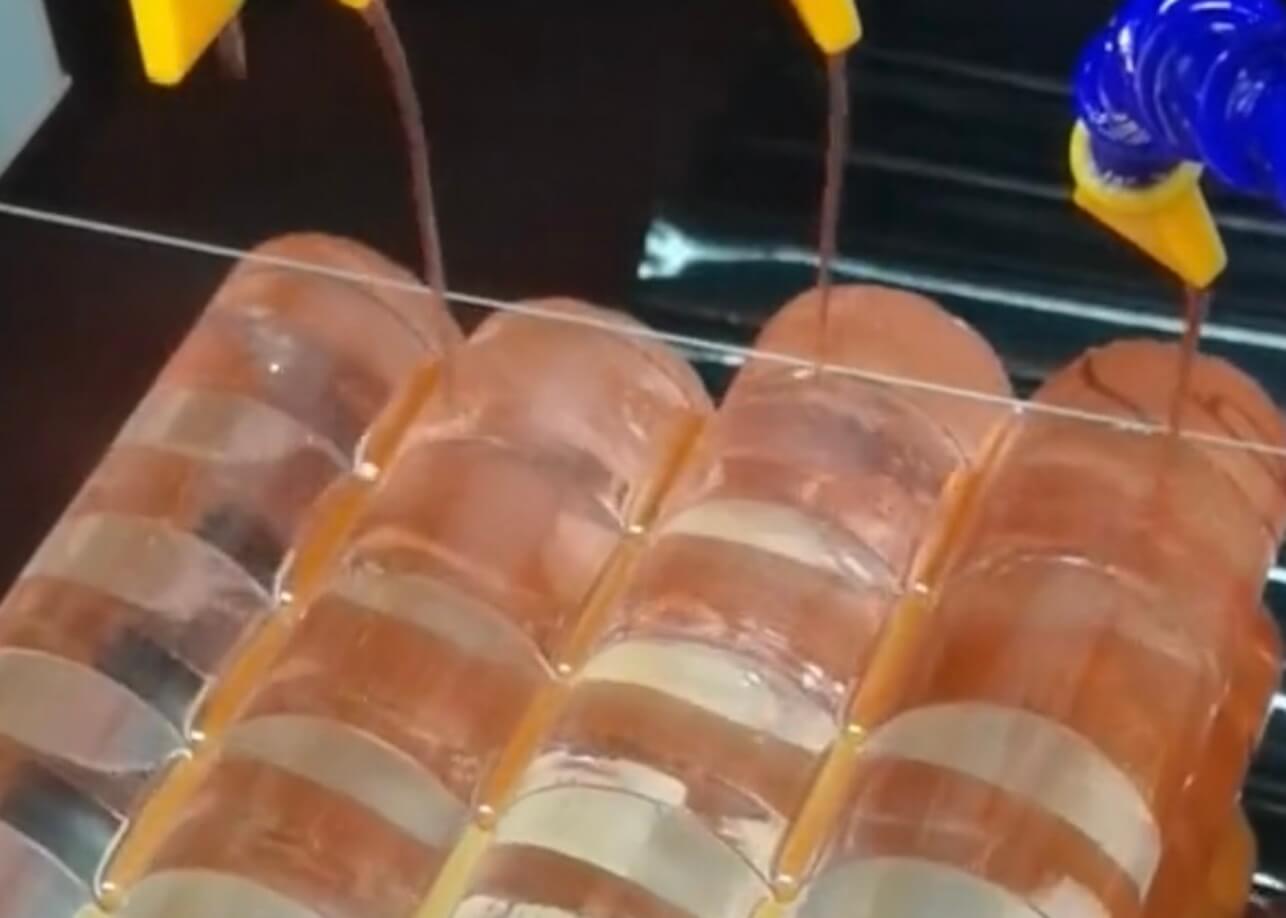

A notable innovation in graphite processing machine is the introduction of circular diamond wire cutting equipment. Unlike conventional wire cutting methods that involve straight wires, circular diamond wire cutting utilizes a continuous loop of wire embedded with abrasive diamond particles. This revolutionary approach offers several advantages over traditional cutting methods, including enhanced precision, efficiency, and reduced material wastage.

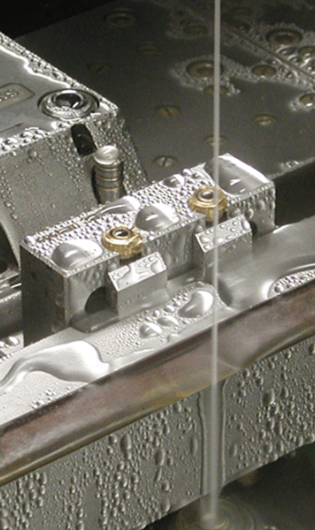

Circular diamond wire cutting equipment boasts several distinctive features that set it apart from conventional cutting methods. The circular wire loop, combined with advanced tension control mechanisms, enables precise and uniform cutting across various graphite materials. Additionally, the use of diamond abrasives ensures superior cutting performance and longevity. Compared to traditional sawing or milling techniques, circular diamond wire cutting offers significant improvements in efficiency and material utilization.

Let’s delve into the key features and benefits offered by this cutting-edge equipment:

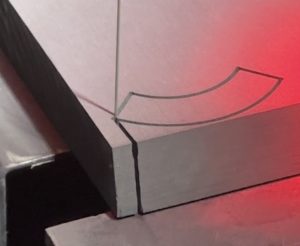

Circular diamond wire cutting equipment harnesses the power of wire cutting, enabling unparalleled precision in graphite processing. The unique flexibility of the wire allows for a full 180-degree change in cutting direction, facilitating the creation of remarkably precise contours and intricate shapes. This capability ensures that even the most complex graphite components are crafted with utmost accuracy, meeting the stringent demands of modern industries.

One of the standout advantages of circular diamond wire cutting lies in the thinness of the cutting wire. This slender wire profile translates to minimal kerf width during cutting, resulting in remarkably small cuts and significantly reduced material wastage. By virtue of its precision and efficiency, this technology minimizes the generation of scrap material, maximizing resource utilization and cost-effectiveness in graphite processing machine operations.

Circular diamond wire cutting equipment boasts a streamlined and straightforward design, engineered for ease of use and operator convenience. Its simple structure and intuitive operation make it accessible to a wide range of users, requiring minimal training or expertise. This accessibility democratizes graphite processing, empowering operators of varying skill levels to achieve exceptional results with confidence and efficiency.

In addition to its precision and efficiency, circular diamond wire cutting excels in delivering superior surface quality in graphite components. The fine cutting wire, coupled with its ability to execute intricate cuts with utmost accuracy, results in impeccably smooth and pristine surfaces. This exceptional surface quality not only enhances the aesthetic appeal of the final product but also ensures optimal performance and functionality in diverse applications.

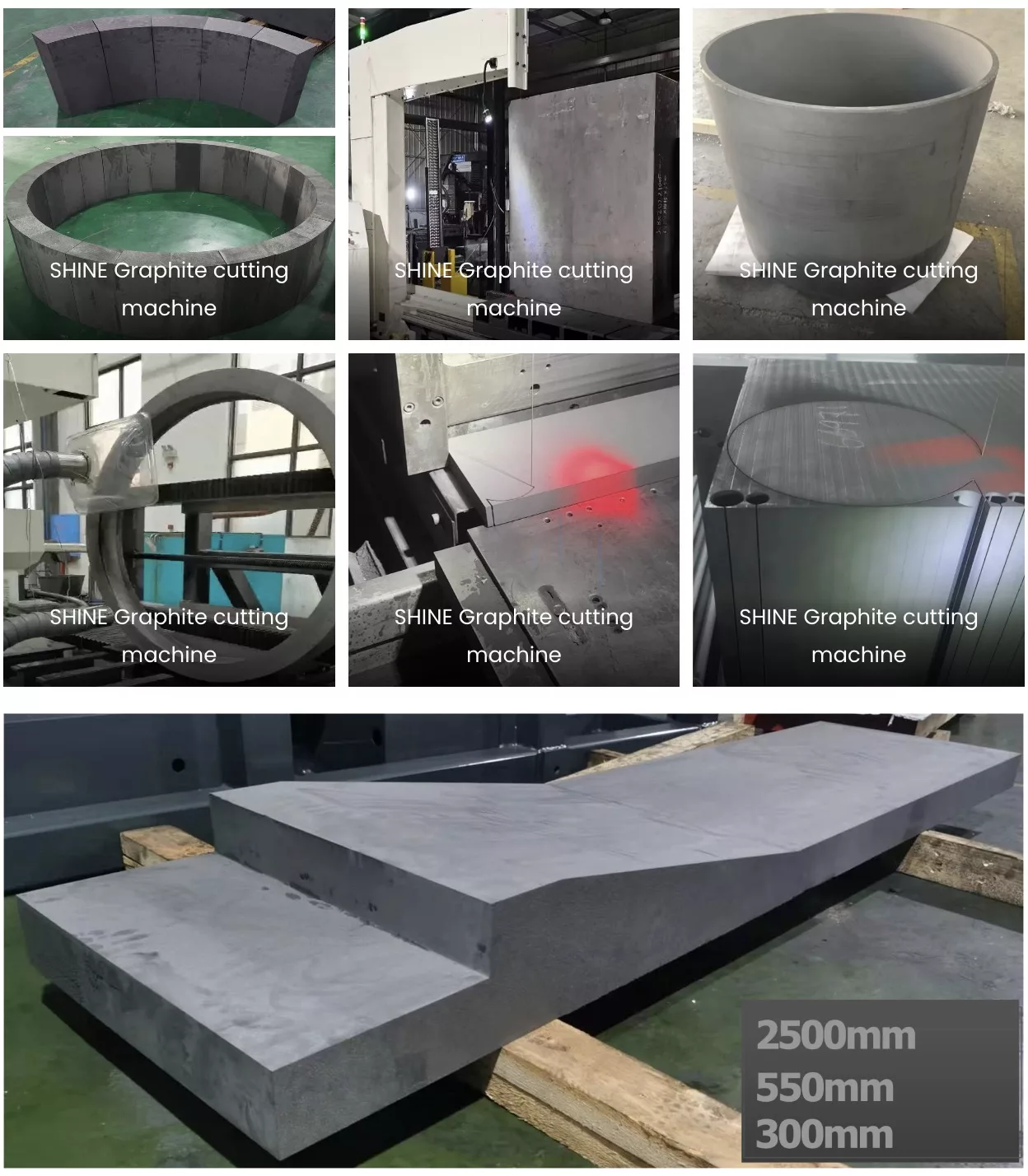

The applications of circular diamond wire cutting equipment as graphite processing machine are vast and diverse. From shaping intricate components for aerospace applications to precision machining of graphite electrodes for electrical discharge machining (EDM), this technology finds widespread use across multiple industries. Its ability to achieve high-precision cuts with minimal material wastage makes it particularly well-suited for applications where accuracy and efficiency are paramount.

Continuous research and development efforts are driving advancements in circular diamond wire cutting technology. Innovations such as improved wire composition, enhanced tension control systems, and integration with computer numerical control (CNC) technology are further optimizing the performance and capabilities of this equipment. As the technology continues to evolve, we can expect even greater efficiency, precision, and versatility in graphite processing machine industries.

Shine Smart Equipment‘s CNC system hardware of the graphite processing machine composed of a fully self-developed embedded specialized system, which is powerful and features wireless remote system update capability. The manufacturer can conduct remote diagnosis and maintenance anytime, anywhere, regardless of where the equipment is sold. that’s also a big innovation

The system features cutting adaptive control, automatic tracking of machining trajectories, real-time display of cutting processes, and convenient operation functions such as machining preview. At the same time, it also has an automatic memory protection function for power failure, ensuring comprehensive protection against various faults such as power outages and system crashes.

Real-world examples underscore the effectiveness of circular diamond wire cutting equipment as graphite processing machine. Case studies highlight successful applications of the technology in various industries, showcasing its ability to deliver superior results while maximizing productivity and cost-effectiveness. Testimonials from industry professionals attest to the transformative impact of circular diamond wire cutting on their operations, driving innovation and competitiveness.

In conclusion, circular diamond wire cutting equipment represents a significant advancement in graphite processing technology. Its precision, efficiency, and versatility have revolutionized the way graphite materials are cut and shaped, opening up new possibilities across industries. As the technology continues to evolve, driven by innovation and research, we can expect further enhancements that will propel graphite processing into the future.