Introduction

A good Optical Glass Cut machine need to be find urgently since a company specializing in optical glass production faced several challenges with its traditional inner circle slicing machines.These challenges were impeding productivity and raising concerns about workplace safety and environment.

The Challenges with Traditional Cutting

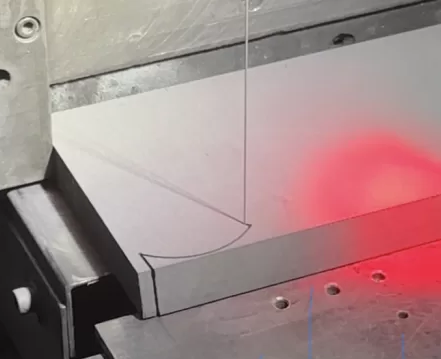

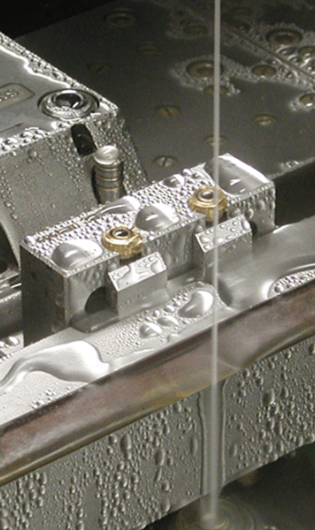

In search of a solution, the company discovered our Endless Diamond Wire Cutting technology and decided to trial our SG30 model. They quickly realized that this new cutting method could address their challenges effectively.

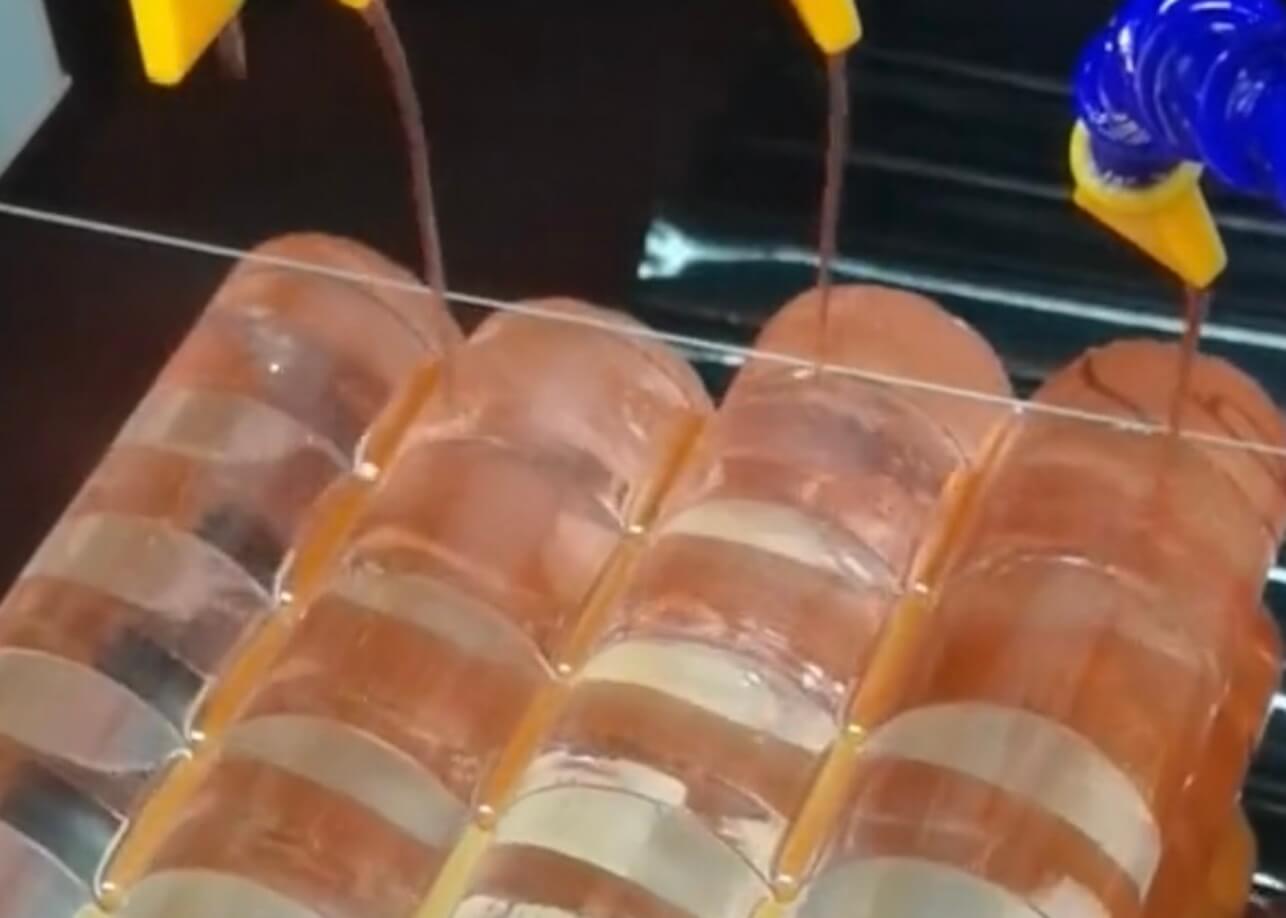

The company was extremely satisfied with the cutting results and overall improvements in production after using the SG30. They particularly appreciated the efficiency of the equipment, the cleaner working environment, and the enhanced safety features. The annular diamond wire cutting technology not only resolved their previous issues but also elevated their production capacity and product quality.

The annular diamond wire cutting technology demonstrated its immense potential and advantages in the mass production of optical glass. By adopting our SG30 equipment, the client successfully overcame the limitations of traditional cutting techniques, achieving a breakthrough in production efficiency, safety, and environmental cleanliness. This case exemplifies the transformative impact of innovative cutting technology in the industrial sector.

The evolution in the methods of Optical Glass Cut is taking a significant leap forward with the adoption of the endless diamond wire cut technique. This cutting-edge approach is transforming the Optical Glass Cut process, offering a level of precision and efficiency that is unparalleled. Particularly for the delicate and exacting requirements of Optical Glass Cut, the endless diamond wire cut method emerges as an innovative solution, ensuring smooth, precise cuts with minimal risk of damage. As the Optical Glass Cut industry continues to seek advancements in accuracy and quality, the integration of the endless diamond wire cut technology is set to redefine the standards in Optical Glass Cut, paving the way for new possibilities in precision glass manufacturing