Introduction

A leading company specializing in large-scale quartz manufacturing encountered several challenges with their existing cutting processes. These challenges were significantly affecting their production efficiency and product quality.

Challenges Faced by the Client

- Limited Cutting Capacity with Inner Diameter Slicing Machines: The client’s traditional inner circle slicing machines were restricted by the size of cutting tools, leading to low production capacity. This limitation hindered their ability to scale operations effectively.

- Slow Cutting Speed with Reciprocating Wire Saws: Their traditional reciprocating wire cutting method was too slow, impacting their ability to meet market demands promptly.

- Edge Chipping with Diamond Band Saws: The diamond band saws they used often resulted in edge chipping on the quartz, compromising the quality of the final product.

Discovery of Our Solution: Large-Scale Quartz Cut

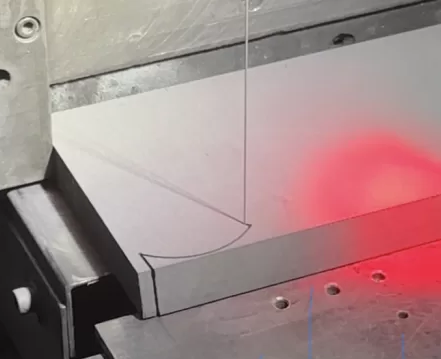

The client discovered our innovative annular diamond wire cutting technology and decided to trial our SH100 model, hoping that this new cutting method could resolve their issues.

Advantages of Our SH60 Equipment

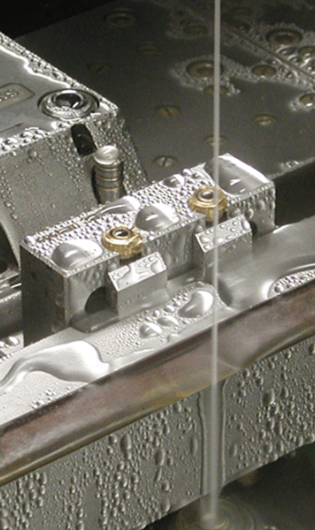

- Enhanced Production Capacity: The SH60’s endless diamond wire cutting technology significantly increased cutting efficiency. Unlike the traditional inner circle slicing machines, the SH60 was not limited by tool size, allowing for larger quartz slabs to be cut efficiently.

- Faster Cutting Speed: Compared to the slow reciprocating wire saws, the SH100 offered a much faster cutting solution, enabling the client to keep up with market demands and reduce lead times.

- Smooth and Precise Cutting: The SH100 reduced the incidence of edge chipping significantly. Its precise cutting capabilities ensured smooth edges on the quartz, enhancing the quality of the final product.

Client Feedback

After implementing the SH60, the client reported a substantial improvement in production efficiency and product quality. They were particularly impressed with the speed and precision , which addressed their initial concerns .

Conclusion

The adoption of our SH60 annular diamond wire cutting equipment marked a turning point for the client in large-scale quartz manufacturing. By overcoming the limitations of traditional cutting methods, they achieved a notable increase in both efficiency and quality. This case study demonstrates the transformative potential of advanced cutting technology in the manufacturing sector, particularly for companies looking to innovate and lead in competitive markets.