This is a story about Complex Profile Cut.Imagine a scenario where a client had a pressing need to cut various shapes from graphite plates, ranging in thickness from 10 mm to a substantial 300 mm. The catch? Graphite is a non-conductive material, rendering traditional EDM wire-cut machines ineffective. Using a bandsaw presented its own set of challenges, including limitations in changing cutting direction and producing less-than-desirable shapes.

In this intriguing case, our client embarked on a quest for the perfect cutting solution. Their journey led them to Shine Wire Cut and our innovative cutting technology. Discover how our solution not only met but exceeded their expectations, ultimately earning their trust and business.

Our client faced a formidable challenge: how to cut intricate and precise shapes from graphite plates of varying thickness. Traditional EDM wire-cut machines, reliant on electricity, were unsuitable due to graphite’s non-conductive nature. Bandsaws, while versatile, couldn’t provide the flexibility needed for intricate cuts, often resulting in less-than-ideal shapes.

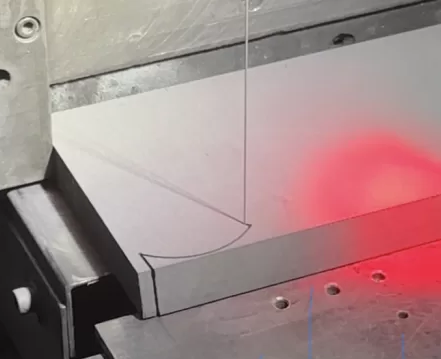

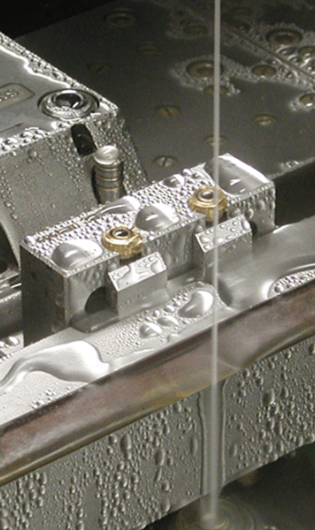

Here’s a detailed look at the cutting process that not only addressed but triumphed over these challenges:

Our client achieved remarkable results:

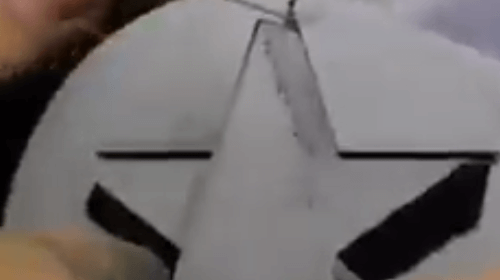

– **Intricate Shapes:** The machine effortlessly cut a variety of complex shapes from the graphite plates, meeting their exact specifications.

– **Efficiency Boost:** Production time was significantly reduced, leading to cost savings and faster project completion.

As the future of Complex Profile Cut technology unfolds, a notable trend is the integration of sophisticated methods like endless diamond wire cut. This advanced technique is poised to revolutionize Complex Profile Cut by providing unparalleled precision and efficiency, especially in cutting intricate shapes and complex designs. With its ability to navigate through challenging materials and intricate patterns, the endless diamond wire cut method is set to become a cornerstone in the realm of Complex Profile Cut. This innovation promises not only enhanced accuracy and reduced waste but also opens up new possibilities in industries requiring detailed and complex cutting solutions.

– **Quality Assurance:** The precision of our machine ensured that each cut was of the highest quality, eliminating the need for post-processing.