| SGC45 Silicon Ingot Cutting Machine | ||

| Parameter | Value or Specification | |

| 1 | Maximum Workpiece Diameter (mm) | 450 |

| 2 | Maximum Workpiece Length (mm) | 1500 |

| 4 | Worktable Y-Axis Travel (mm) | 400 |

| 5 | Worktable Z-Axis Travel (mm) | 500 |

| 10 | Maximum Diamond Wire Speed (m/s) | 36 (Max) |

| 13 | Minimum Feed Increment X-Axis (mm) | 0.01 |

| 14 | Minimum Feed Increment Y-Axis (mm) | 0.01 |

| 15 | Repeat Positioning Accuracy X-Axis (mm) | ±0.02 |

| 16 | Repeat Positioning Accuracy Y-Axis (mm) | ±0.02 |

| 20 | Total Power Consumption (kW) | 3.5 |

| 21 | Power Supply (Three-phase Five-wire) | AC220V 50Hz |

| 22 | Air Supply (MPa) | 0.6 |

| 23 | Machine Size(mm) | 2000*1200*1800 |

| 24 | Machine weight(kg) | 1800 |

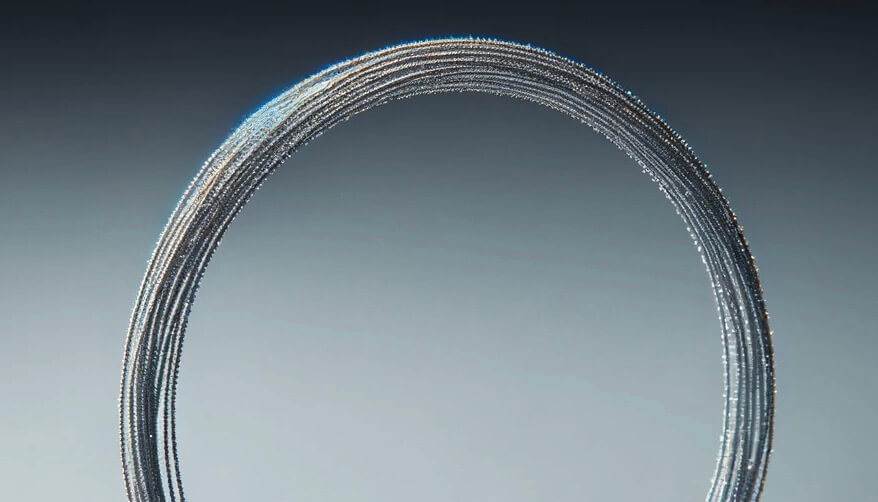

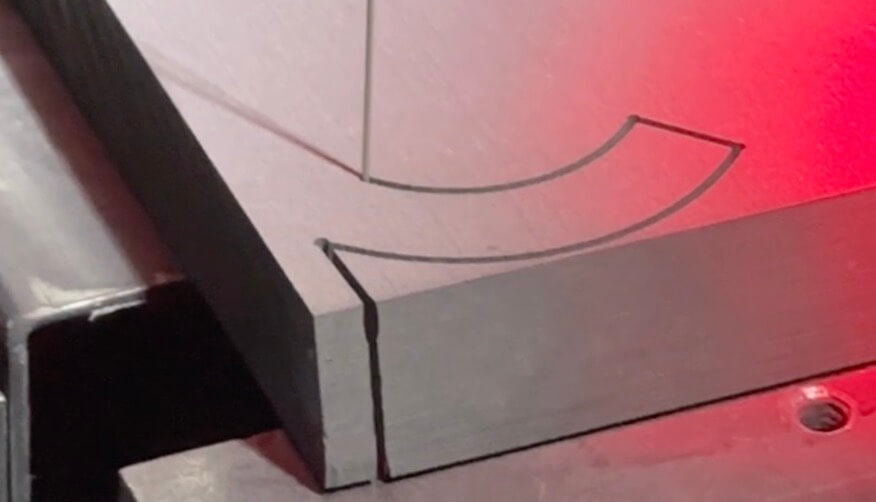

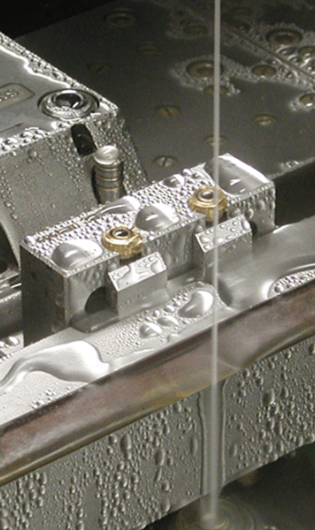

This device is a diamond cutting equipment specifically designed for the semiconductor and photovoltaic industries to do Silicon Ingot Cutting . The cutting tool used is the latest closed-loop diamond wire, capable of segmenting the silicon rod and taking slices/seeds after the cutting process.

SGC45 is designed for the cutting of 18-inch silicon rods, while a similar structure, SGC30, is suitable for cutting 12-inch silicon rods.

Compared to diamond band saws and traditional single-wire cutting devices, this circular or endless diamond wire cutting equipment exhibits a lower edge chipping rate, superior cutting surface quality, and reduced material wastage.

Click To Watch More Videos Showing Our Cutting Machine In Action.

Pictures of Success Silicon Ingot Cutting

![]()