In industrial manufacturing, choosing the right cutting tool is critical to performance, cost-efficiency, and product quality. Among the most widely used solutions are the wire saw and the band saw. Each has distinct characteristics suited for specific materials and applications. This article explores their core differences, strengths, and use cases to help manufacturers make informed decisions.

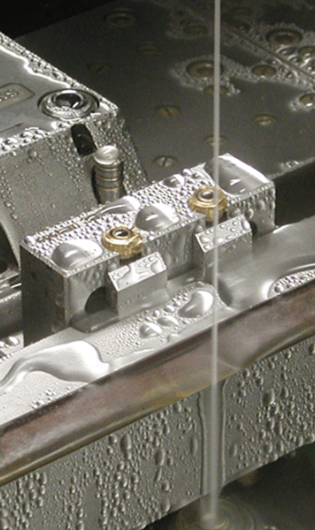

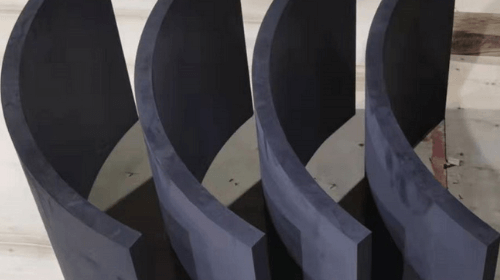

A wire saw uses a continuous or endless diamond-coated wire to cut through hard materials such as silicon wafers, graphite blocks, ceramics, or sapphire. The wire’s thin profile—sometimes as small as 0.35 mm—allows for highly precise cuts with minimal kerf loss and dust generation.

Key advantages of wire saws:

Superior precision: Ideal for applications where tolerances are tight and surface integrity is critical.

Low kerf loss: Thinner wire results in less material waste.

Minimal mechanical stress: Cuts are achieved through abrasion rather than force.

Broad material compatibility: Used in semiconductor, solar, and advanced materials industries.

The band saw is a more traditional cutting tool that uses a serrated blade rotating around two wheels. It is widely used for metal, wood, and plastic cutting in general manufacturing, construction, and fabrication environments.

Key advantages of band saws:

High throughput: Ideal for cutting large volumes of material quickly.

Low upfront cost: Equipment is generally less expensive than precision wire saws.

Broad blade types: Adjustable for different materials and thicknesses.

Simple operation: Common in general-purpose workshops and factories.

However, band saws generate more kerf loss, mechanical vibration, and dust, which may not be suitable for high-precision industries.

|

Feature |

Wire Saw |

Band Saw |

|---|---|---|

|

Cutting Precision |

Very High (micron level) |

Moderate to Low |

|

Material Loss (Kerf) |

Very Low (as low as 0.4 mm) |

Higher (depending on blade thickness) |

|

Surface Finish |

Smooth, minimal post-processing |

Rougher, often requires finishing |

|

Cutting Speed |

Moderate |

Fast |

|

Suitable Materials |

Silicon, graphite, ceramics, sapphire |

Metals, wood, plastics |

|

Initial Investment |

Higher |

Lower |

The choice between a wire saw and a band saw depends heavily on application requirements:

If precision, material conservation, and surface quality are your top priorities—especially for cutting brittle or advanced materials like silicon wafers or graphite—then a wire saw is the better choice.

If your focus is on high-speed processing of metals or structural materials in a general-purpose setting, a band saw offers greater efficiency at a lower cost.

Both wire saws and band saws serve critical roles in industrial cutting, but they are far from interchangeable. Wire saws excel in fine, low-damage cuts, especially for high-value and delicate materials. In contrast, band saws offer speed and versatility for broader industrial applications.

When choosing between the two, manufacturers should weigh precision needs, material types, and long-term operational costs. Selecting the right saw ensures not only higher productivity but also improved end-product quality.