| Item | Specification | Parameters |

| Performance | Stable Operating Linear Speed | ≥2400 m/min |

| Processing Capability | 180mm x 180mm – 232mm x 232mm | |

| Workpiece Length | ≤900mm x 1 piece or equal length spliced rod (monocrystalline) | |

| Main Rollers Number/Drive Power | 3 rollers/80Kw, water-cooled | |

| Wire Rollers Number/Drive Power | 2 axes/22Kw, water-cooled | |

| Roller Diameter x Length | 190mm (3 rollers), rubber-coated 916mm, slotted 900mm | |

| Wire Running Method | Bidirectional/Unidirectional | |

| Wire Guide Wheels | 160mm, total of 6 (3 on each side) | |

| Axis Distance | 440mm (for 230mm x 230mm silicon wafers) | |

| Feed Speed | 0~10mm/min | |

| Feed Slide Fast Movement Speed Range | 30-500mm/min | |

| Feed Slide Slow Movement Speed Range | 5~30mm/min | |

| Performance | Worktable Feed Straightness | ≤0.005mm/150mm |

| Acceleration | Up to 10m/s^2 | |

| Tension System | 0-25N, fluctuation range ≤±0.1N | |

| Spindle Runout | ≤3μm | |

| Main Roller (core) Runout | ≤10μm | |

| Wire Unwinding/Winding Reel (including working area) Runout | ≤20μm | |

| Wire Unwinding/Winding Reel Model and Maximum Wire Storage | PV600HD/100km (stroke 200mm) | |

| Cutting Fluid Tank Maximum Capacity | 600L, maximum flow rate Max250L/min (directly below the cutting chamber) | |

| Cutting Fluid Pump Power | 7.5KW | |

| Equipment Vibration Value | When running wire at 900m/min, the vibration of the cutting chamber main body, and bearing box ≤10gE | |

| Bearing Box Cooling Method | Internal circulation water cooling | |

| TTV | ≤20μm |

It is a specialized precision cutting equipment for various hard and brittle materials such as silicon wafers, semiconductors, glass, etc. This machine adopts our company’s latest technology, featuring sensitive response and significantly reducing the risk of fine wire breakage.

1.High-speed cutting is realized, with a cutting speed of ≥2400 m/min and tension control accuracy of ±0.1N.

2.It adopts a complete Siemens/Huichuan servo system solution, achieving stable and high-precision cutting methods, producing silicon wafers, semiconductors, glass, and other materials that meet the requirements.

3.The wire collection and deployment sides introduce the shortest path into the cutting chamber, enabling bi-directional wire feeding.

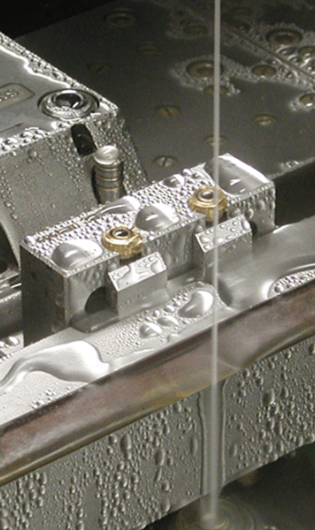

4.The machine’s body is a cast piece, offering very high mechanical stability and thermal stability, thus ensuring the smoothness of the cutting process.